Pre-engineered buildings (PEB) have revolutionized the construction industry by providing a flexible, efficient, and affordable alternative to traditional construction methods. One of the key aspects contributing to PEB’s success is PEB detailing. But what exactly is PEB detailing, and why is it so important?

Understanding PEB Detailing

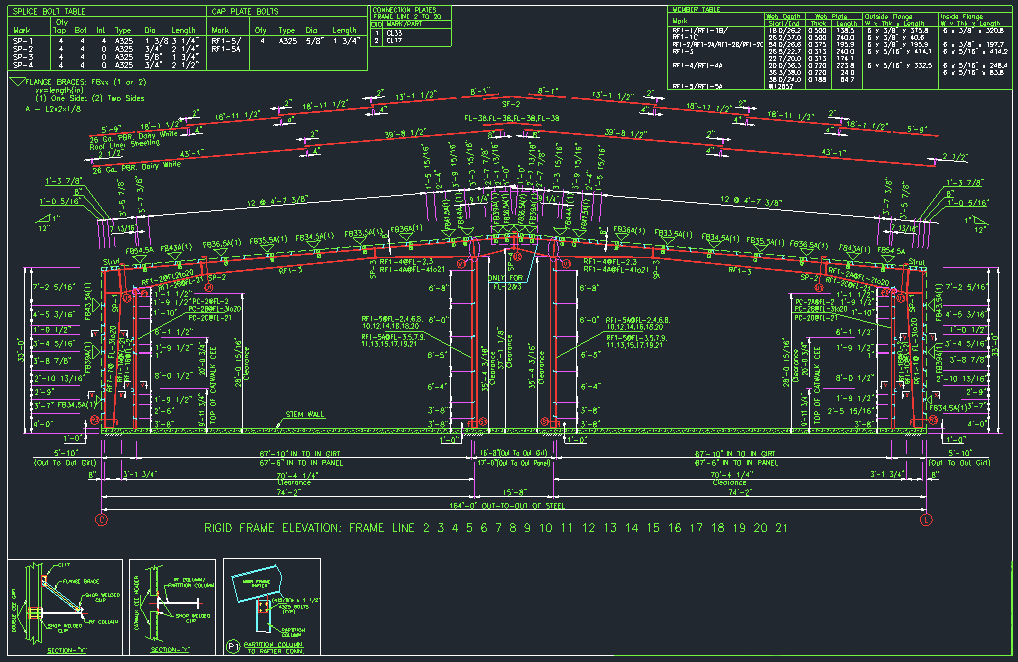

PEB detailing involves the comprehensive planning and detailing of every pre-engineering building component. This includes everything from the structural elements like columns, beams, and purlins, to the cladding materials, doors, windows, and even the nuts and bolts that hold everything together.

PEB detailing is a meticulous process that requires a high level of precision and expertise. It involves creating detailed drawings and plans that guide the manufacturing and assembly of the building. These drawings provide a visual representation of the building, allowing everyone involved in the project to understand how the various components fit together.

The Importance of PEB Detailing

PEB detailing plays a crucial role in the construction of Pre-Engineered Buildings for several reasons:

1. Accuracy:

PEB detailing ensures that every component of the building is accurately designed and planned. This reduces the chances of errors during the manufacturing and assembly stages, saving time and resources. Inaccuracies in the detailing process can lead to costly mistakes and delays, making accuracy a top priority in PEB detailing.

2. Efficiency:

With PEB detailing, every part of the building is designed to fit together perfectly. This not only makes the assembly process quicker and more efficient but also results in buildings that are structurally sound and durable. The efficiency of PEB detailing also extends to the manufacturing process, as the detailed plans allow for the optimal use of materials, reducing waste and lowering costs.

3. Customization:

PEB detailing allows for a high degree of customization. Whether it’s the building’s size, shape, or functionality, PEB detailing can accommodate a wide range of design specifications. This flexibility makes PEB an attractive option for a variety of applications, from warehouses and factories to offices and retail spaces.

4. Cost-Effectiveness:

By optimizing the design and reducing waste, PEB detailing can significantly reduce the overall cost of the building. This makes PEB a cost-effective solution for a wide range of applications. The cost savings extend beyond the initial construction costs, as the efficiency and durability of PEB buildings result in lower maintenance and repair costs over the life of the building.

Conclusion

In conclusion, PEB detailing is an integral part of the PEB construction process. It contributes to the accuracy, efficiency, customization, and cost-effectiveness of Pre-Engineered Buildings, making it a vital activity for any PEB fabricator. As the construction industry continues to evolve, the importance of PEB detailing is only set to increase, making it a key area of focus for anyone involved in the design, manufacturing, or assembly of Pre-Engineered Buildings.